CMDB Factory solution

Many manufacturing companies lack a complete and up-to-date overview of all assets in the company. Often, this shortcoming has developed over time, for example due to rapid growth of the company.

The (partial) information gap occurs in various ways. In some cases complete systems are hardly documented. In many cases changes to hardware components, model numbers, (old) applications, or version updates are not processed. Sometimes this knowledge is present somewhere in the company, but not accessible for the people who work with it. Occasionally we see a total blank spot in knowledge of components that are vital for the production processes. Fortunately, you can solve this, thanks to our CMDB Factory Solution.

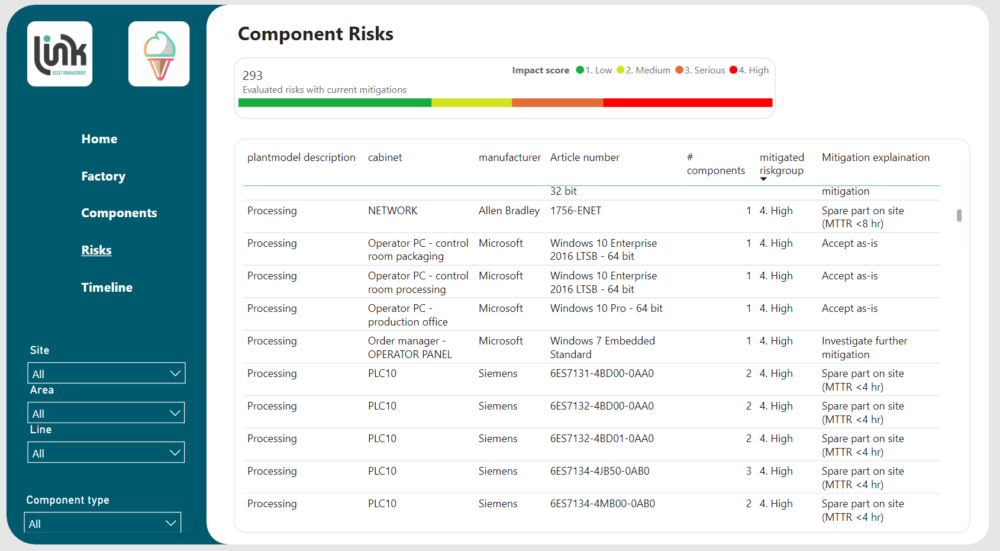

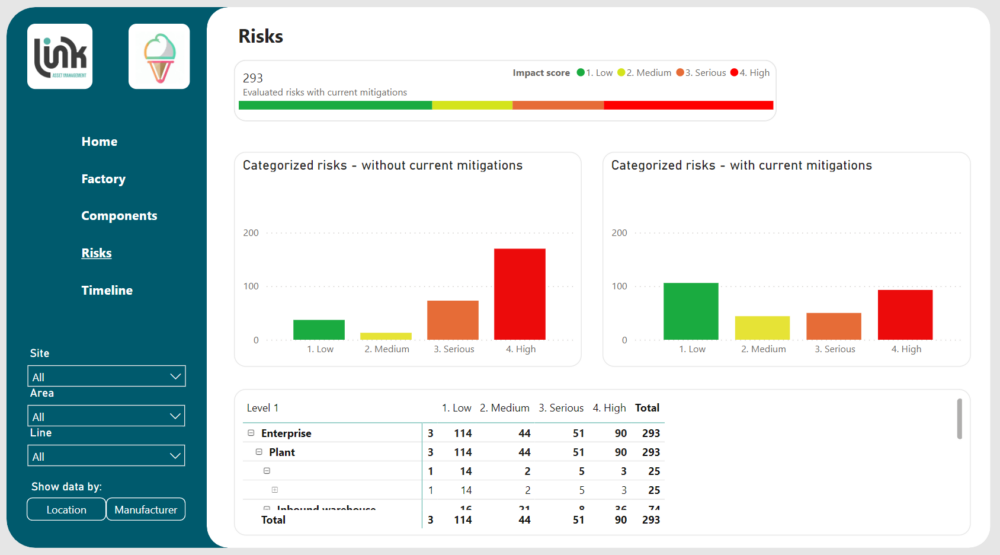

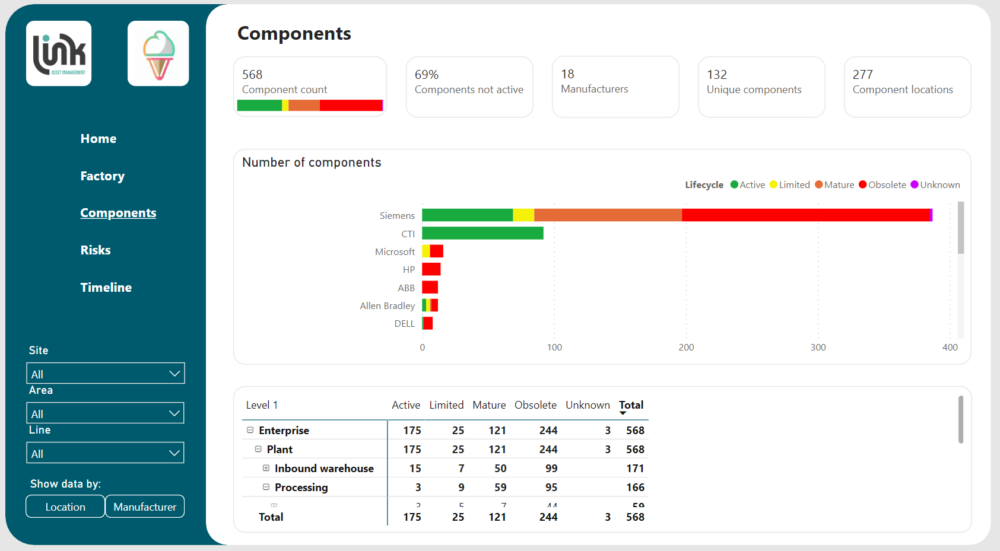

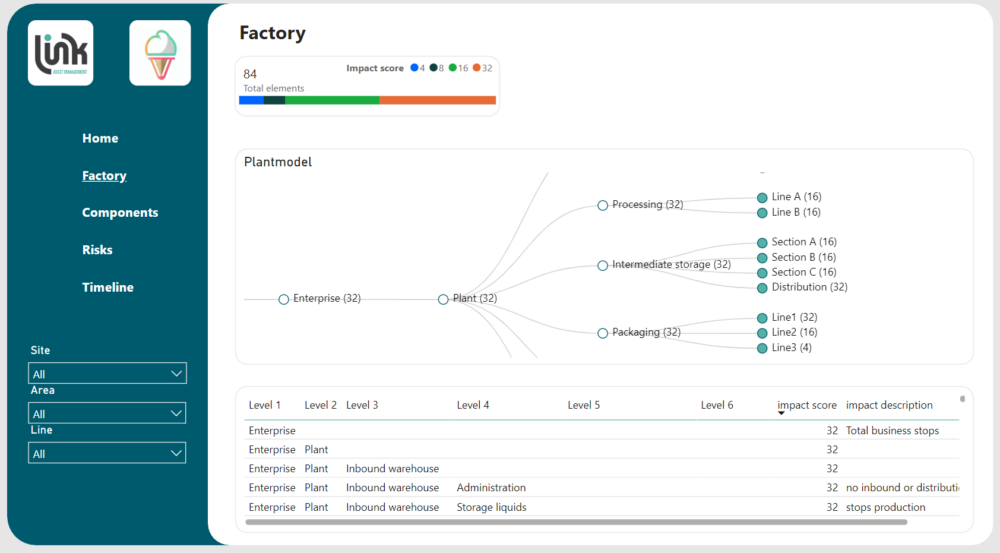

Clear dashboard

All data is summarized and displayed very clearly on a dashboard, allowing you to manage total overviews and zoom in to a detailed level.

Benefits of our solution

Up-to-date and detailed

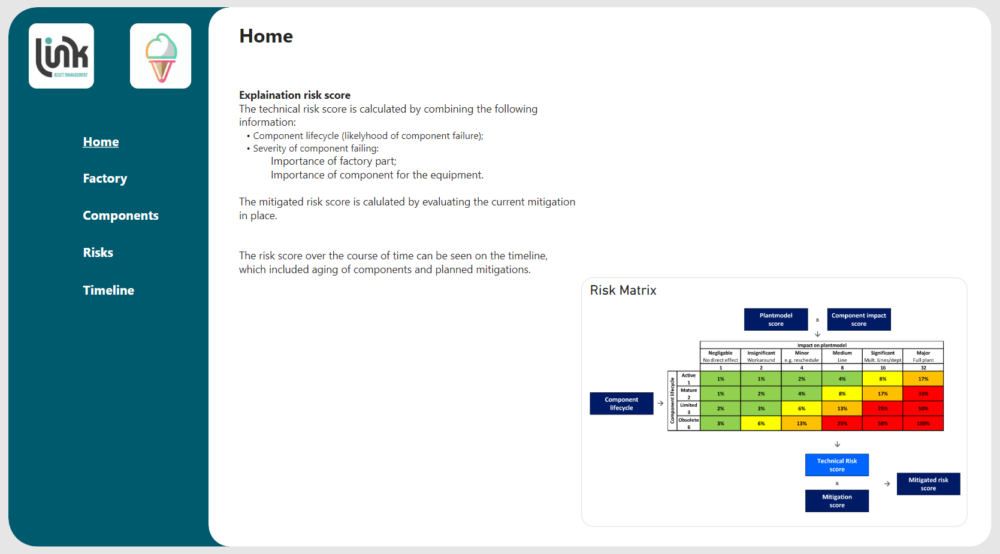

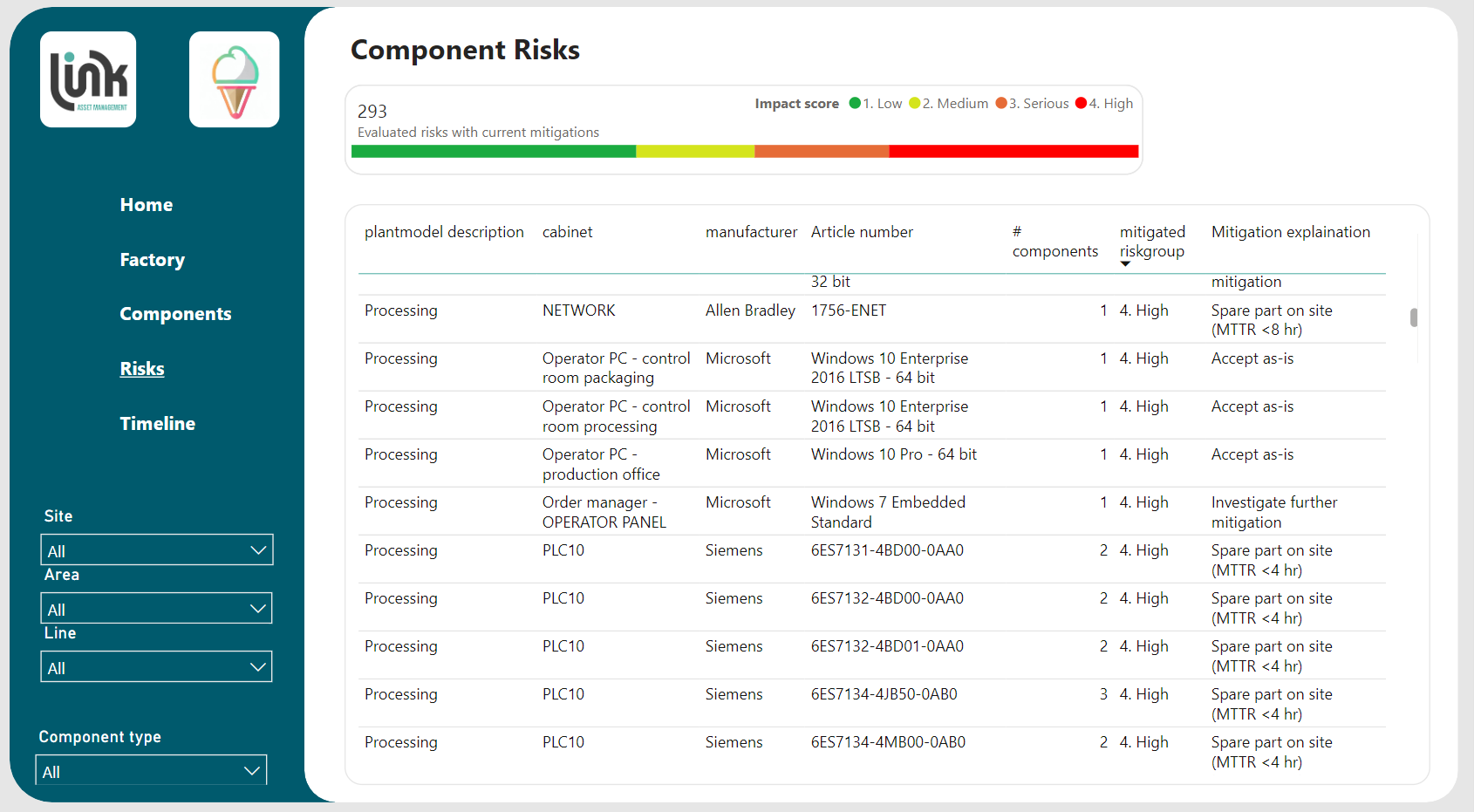

A management dashboard with highlights combined in one system with and complete and detailed overview of all assets, versions, lifecycle, and associated risks for business continuity.Clear prioritization

At a glance, it's clear where to focus and which actions should have priority.Fact based maintenance

Create maintenance plans based on correct, up-to-date data. This reduces downtime, increases productivity, and assures budgets are used effectively.What makes our solution unique?

Link between component and impact

We link all components to a model of your plant, making the impact of (impending) failures immediately visible.Risk vs mitigation

The risk inventory is followed by a mitigation proposal, based on a detailed analysis of your production environment.Changing risk profile

As lifecycle information on your assets is kept up-to-date, the risk profile always matches the current situation. You can even see when assets will become problematic in the future.Our approach

Required for an up-to-date and reliable risk profile is to have a complete and correct overview of all assets and components in your production environment. That’s why we offer our solution in combination with a full inventory.

We map all assets in a plant model and document everything in our CMDB solution.

Then we train all users in the use of our online platform. If desired, we periodically update all data.

The process

The implementation of CMD Facotry Solution proceeds as follows:

- Creation of a Plant Hierarchy (a schematic representation of your process);

- Creation of a complete overview of all systems, components, and software used in your process;

- Linking the components to their place in the process;

- Scoring risks score at component level (what are the consequences if a component fails?);

- Documentation of mitigating measures already in please (e.g. spare parts, back-up procedures);

- Definition of a mitigation plan;

- User training;

- Implementation of the platform.

Make your factory future proof

Are you interested in improving the management of your assets, increasing the effectiveness of you maintenance budget and reducint downtimes? Contact us for demo, additional information, or a customized plan.